Feintool Launches FeinAl Plus: The Next-Gen Sustainable Wear Protection for Metal Forming Tools

Feintool Launches FeinAl Plus: The Next-Gen Sustainable Wear Protection for Metal Forming Tools

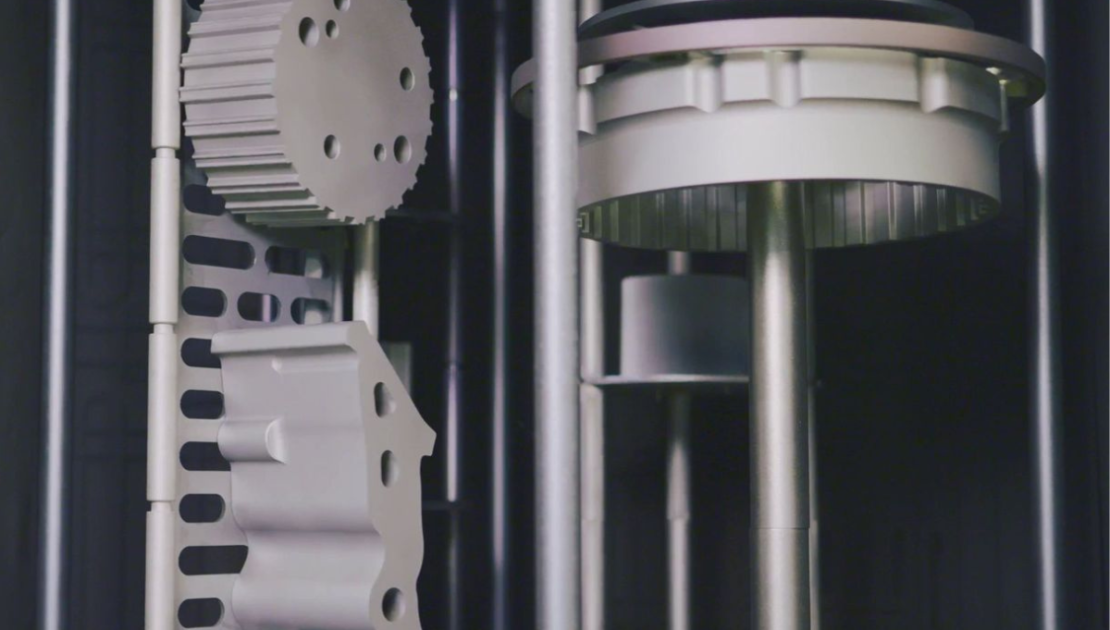

Swiss company Feintool, a leading provider of precision metal forming solutions, has unveiled its new technology, FeinAl Plus, which offers improved wear protection for metal forming tools. The technology uses advanced materials and surface treatment techniques to enhance the durability and lifespan of metal-forming tools, reducing the need for frequent replacements.

The manufacturing industry has historically been associated with high ecological impacts, particularly in terms of energy consumption and waste generation. Feintool’s Feinal Plus technology has the potential to address these challenges by reducing the number of raw materials required for tool production and minimizing the waste generated from the disposal of worn-out tools.

The technology’s high durability and wear resistance also significantly reduces the need for frequent tool replacements, reducing energy consumption during the manufacturing process. This translates to reduced emissions, making it more environmentally friendly.

The technology contributes to the circular economy principles by promoting the efficient use of resources and waste reduction. It extends the lifespan of metal-forming tools, reducing waste and promoting sustainable practices.

Feintool’s FeinAl Plus technology is a significant step towards a more sustainable metal-forming industry, which is essential in addressing the pressing environmental challenges facing the manufacturing sector.